The number one priority in any response is safety the safety of workers, property, and the environment. If requested to do so by a member company who has had a spill, the SEAPRO Safety Manager will assume the role of Safety Officer and perform the duties outlined for that position in SEAPRO Safety Checklist, including site assessment, site characterization, and the preparation of a Site Safety and Health Plan, as well as those duties described below. Specific information on SEAPRO safety policies and guidelines is presented in this section, as well as forms and guidelines for use by SEAPRO member companies in developing their own policies and plans.

The Safety Officer is responsible for monitoring and assessing hazardous conditions and unsafe situations. This person is also responsible for developing the oil spill incident “Site Safety Plan” to assure personnel safety. The Safety Officer will correct unsafe acts or conditions through regular lines of authority, although the Safety Officer or his Field Safety Personnel may exercise emergency authority to stop or prevent unsafe acts when immediate action is required.

Duties outlined above are established in U.S. Coast Guard Incident Management Handbook (IMH (2014)) responsibilities for the incident Safety Officer.

SEAPRO is responsible for providing safe working conditions for its response teams. These responsibilities are covered in various safety laws as well as OSHA HAZWOPER regulations, and include a requirement for the employer to provide both safety equipment (including personal protective gear) and safety training to a certain level. SEAPRO maintains compliance and provides its response pool members with both the proper equipment and the proper level of training (HAZWOPER as well as other training).

SEAPRO has available a variety of air monitors for establishing the safety of air quality at a spill site or work zone. All air monitors are caliberated and tested on a regular basis, as well as prior to any field deployment or use.

SEAPRO has the following air monitoring equipment in active inventory:

More detailed specifications on all of SEAPRO's air monitors can be found on the SEAPRO Website. The air monitoring equipment is stored at the SEAPRO office in Ketchikan.

All Personal Protective Equipment (PPE), except Mustang Suits, is stored in special responder bags inside certain SEAPRO containers. Mustang Suits are packed separately, 6 per box. The quantities, zone location, and container numbers for the responder bags and mustang suits can be seen by clicking on their respective hyperlinks.

Safety and health is the prime responsibility of all individuals during spill response activities. Anyone can stop any activity at any time if he/she believes there is a safety concern. Once stopped, the person in charge (generally the team leader) must resolve the safety concern(s), and only then can the response continue. Although SEAPRO's goal is to successfully clean up an oil spill, we will never place spill cleanup over the preservation of human health and safety.

All workers at a spill site should have received spill response training, during which safety training has been stressed. All personnel at a spill must remember that everyone is a safety observer and, regardless of what their job assignment may be, safety comes first.

The Minimum Elements to review at a spill site appear below and in the Safety Checklist. Each spill responder should review the Minimum Elements Checklist and sign at the bottom acknowledging such review.

MINIMUM ELEMENTS For Worker Site Entry Before Written Safety Plan Is Complete

ABATEMENT

BRIEFING WORKERS

PERSONAL PROTECTIVE EQUIPMENT (PPE)

EMERGENCY MEDICAL

COMMUNICATIONS

SITE SPECIFIC HEALTH and SAFETY PLAN

CHECKLIST REVIEWED ______/_______/_________ BY:___________________________

The Site Safety and Health Plan (SSHP) that is specific to each incident contains information to help personnel work safely. Personnel at oil spill clean up sites should familiarize themselves with the SSHP, and sign it prior to starting response activities. Basic health and safety guidelines ar as follows;

Additionally, SEAPRO provides training and resource materials for responders and Response Team members. The SEAPRO RESPONDER HANDBOOK provides information regarding safe work practices, site management, clean up protocols, and best practices.

The following insert provides safety considerations outlined in the SEAPRO RESPONDER HANDBOOK.

SEAPRO safety equipment (which includes decontamination supplies, the "PPE/Safety Module", and Mustang Suits) is stored in 20-ft. containers along with SEAPRO oil spill response equipment (skimmers, boom, pumps, etc.). These response containers are located in each of SEAPRO's nine zones. (See Section 1 - SEAPRO Equipment for the specific location of the containers in each zone.)

If it is determined that an Industrial Hygienist is needed, one of the consultants listed below will be contacted and requested to make arrangements through the Logistics Section to travel to the spill site. Until the arrival of the Industrial Hygienist, the SEAPRO Safety Manager or other qualified SEAPRO personnel will assist a member company in completing the Site Characterization and Site Safety and Health Plan. SEAPRO personnel will use the air monitoring equipment described above. (see SEAPRO Air Monitoring Equipment).

| (1) Mr. Steven Magasis M..S., C.I.H. | (2) Mr. Martin Finkel |

| Golder Associates, Inc. | |

| 4104 - 148th Ave. NE | 200 W. 34th Ave., Suite 908 |

| Redmond, Washington 98052 | Anchorage, Alaska 99503 |

| Office - (206) 883-0777 ext. 2259 | Office - (970) 248-1024 |

| Alt Office (206) 784-9980 | |

| Emergency Pager (206) 986-0734 | |

| Fax - (907) 248-1024 |

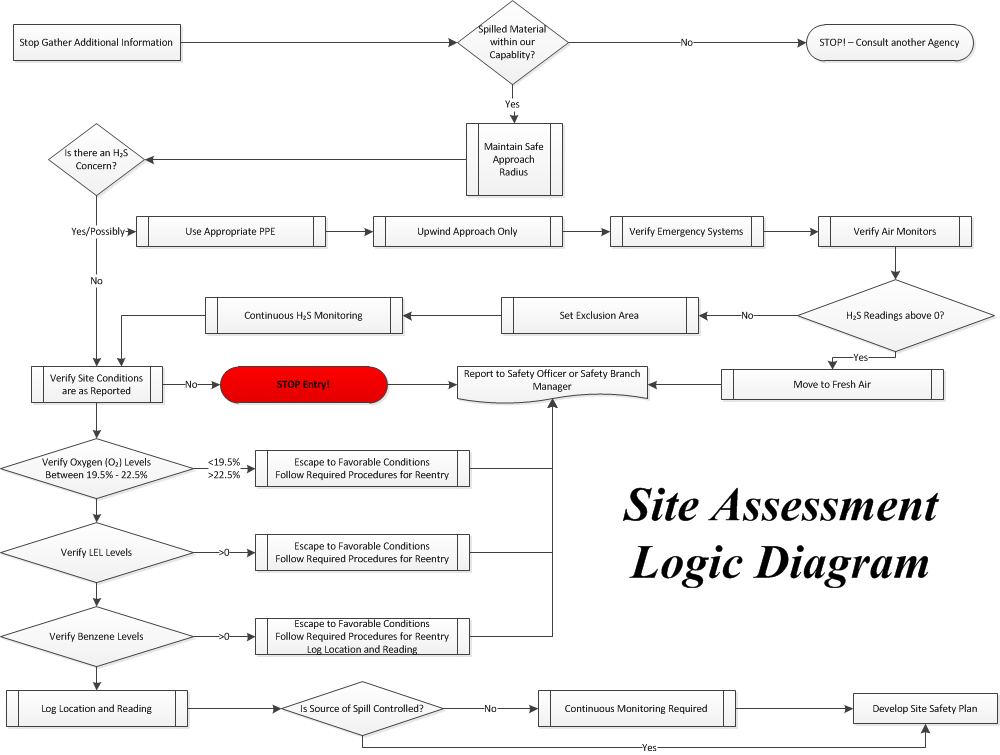

The following diagram provides a step-by-step guide for completing the initial site assessment.

The site of a spill must be characterized prior to preparing a Site Safety & Health Plan. To assure that the site characterization and hazard analysis is done safely and properly, the SEAPRO Safety Officer performs the following survey before actually entering the site.

Task Specific Risk Assessment (TSRA)

STOP! & Think |

||

|---|---|---|

Before starting any work:

|

||

| Pre-entry Survey | ||

| Begin Monitoring from: |

|

|

| Monitor for: |

|

|

| Begin Monitoring at _______ Miles from the Origin | ||

| Monitor at _________ (Mile/Time) Intervals | ||

| Monitoring Required for the following Contaminants: | ||

| _____ Verify Use of the Buddy System | ||

| Personal Protection Equipment Requirements | ||

| Check if Required | Description | Specific Description |

| PFD | ||

| Floatsuit (Type V) | ||

| Emergency Signaling Device | ||

| Eye Protection | ||

| Skin Protection | ||

| Safety Boots/Shoes | ||

| Hard Hat | ||

| Hearing Protection | ||

| Gloves | ||

| Respiratory Protection | ||

| Emergency Instructions | ||

| Yes - There is a risk No - There is no risk |

||

| Chemical Hazards | Ergonomic Hazards | Environmental Hazards |

|

|

|

| Access/Egress Hazards | Electrical/Hot Work Hazards | Overhead Work/Fall Hazards |

|

|

|

| Rigging Hazards | Personal Limitations/Hazards | Personal Protective Equipment (PPE) |

|

|

|

| Team:____________________ | Date:____________________ | ||||

| Readings | |||||

|---|---|---|---|---|---|

| Location: | Time: | ||||

| On-Scene Weather | |||||

| Wind Speed: | Wind Direction: | Temperature: | Water Temp.: | Current Direction: | Current Speed: |

| Visual Assessment | |||||

| Light Sheen: | Medium Sheen: | Heavy Sheen: | |||

| Wildlife Impacted | |||||

| Birds: | Seals: | Sea Lions: | Sea Otters: | Sea Mammals: | Fish: |

| Comments: | |||||

Once the Pre-entry Survey and Site Characterization and Hazard Analysis are complete, the Safety Officer will prepare the Site Safety and Health Plan.

Proper hazard identification, hazard assessment, and selection of the appropriate personal protective equipment and safety and health practices must precede all other activities for spill containment and control.

Chemical exposure potential, fire and explosion risk, temperature extremes,

and other physical hazards must be carefully considered in mobilizing a response

effort. The development of a Site Safety & Health Plan that incorporates all these

considerations is required by the Occupational Health and Safety Organization (OSHA)

under 29 CFR 1910.120. Furthermore,

the plan must also meet State regulations regarding occupational safety and health as

described in the general safety code, occupational health and environmental control

code, construction code, petroleum code, hazardous waste operations, and emergency

response and hazard communications code.

In order to assist member companies in the preparation of their individual site safety

plans, SEAPRO provides one of its Site Safety & Health Plan formats. This

plan was developed by NIOSH, OSHA, USCG, and the EPA for responding to hazardous materials

releases. While it is readily adaptable to different situations and facilities, it is

important to note that this plan is not all-inclusive and should only be used as a guide.

A Site Safety & Health Plan contains various sections including:

The Site Safety Plan, which typically includes the Health Plan is available as an ICS form (ICS-208 & ICS-206) which is available in a variety of formats and form factors.

Additionally, SEAPRO has developed an online application that will help safety Personnel quickly prepare an initial Site Specific Safety and Health Plan. You can get started here.

State of Alaska regulations regarding the contents of oil discharge and contingency plans under 18 AAC 75.425 specify that the following information be included within the Safety Regulations section of a plan:

"Based on applicable safety standards, a description of the steps necessary to develop an incident-specific safety plan for conducting a response."

ADEC Oil Discharge Prevention and Contingency Plan Application and Review Guidelines provide, in part, the following information regarding required contents of this section:

"The Safety Officer for the facility or operation must be identified

by name and/or title and contact number. The duties of the Safety Officer in the

event of a spill must be described.

Operations required by the Occupational Safety and Health Administration are to have

a site-specific safety plan to guide response to a spill. This section of the plan must

describe the procedures for developing and implementing an incident-specific plan to

guide response in accordance with applicable federal and state standards."